Stochastic particle models for quantification of relationships between process parameters, structural characteristics and material properties

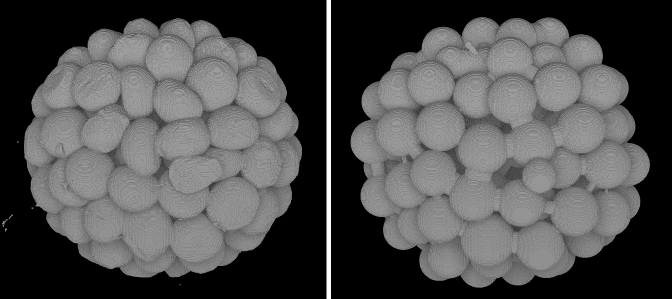

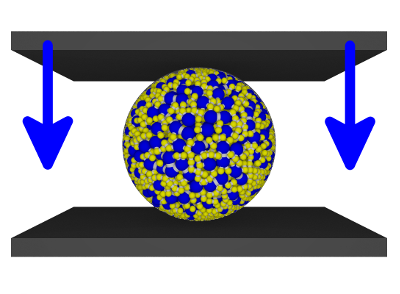

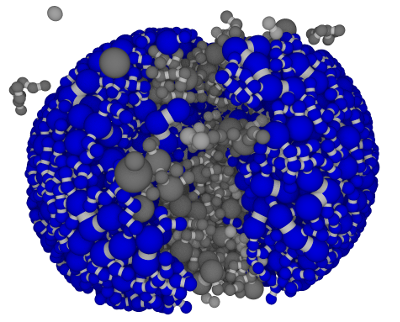

The quantitative description of solids (e.g., primary particles, granules, aggregate materials) using disperse structural characteristics and material properties plays a key role for flowsheet simulations of dynamical solids processes. This is caused by the well-known fact that material properties (e.g., mechanical properties like elastic modulus and fracture behavior) often depend on the 3D morphology. On the other hand, the 3D morphology itself is controlled by the solids process and its process parameters. In this project we develop two kinds of stochastic models that will both be used to quantify the relationship between process parameters, structural characteristics (e.g., for particle size, particle shape and inner structure) and material properties. We will investigate stochastic models applicable for an aggregate description of solids, i.e., we will identify (parametric and copula-based) multivariate probability distributions that can be used to model disperse structural characteristics of solids, their material properties and their complex dependencies. This type of stochastic model provides a basis to statistically analyze simulated and experimental data, which are generated by partner groups of the SPP 1679 for different scenarios w.r.t. materials and processes, and permits the prediction of material properties based on a pure statistical background. Furthermore, we will develop stochastic simulation models for 3D microstructures with techniques from stochastic geometry. The developed models can be used as input for process simulations examined in our partner groups. We will implement these models for primary particles and granules in the first funding period. In the following funding periods, these modeling approaches will be extended: we will also consider aggregate materials (e.g., tablets), where the spatial arrangement of particles is important, and we will incorporate multi-phase materials into these models.

This project is supported by the Deutsche Forschungsgesellschaft (DFG) in the priority programme SPP 1679 "Dynamic Simulation of Interconnected Solids Processes".

Contact persons: Prof. Schmidt, Aaron Spettl