Zusatzinformationen

Vereinigung für allgemeine und angewandte Mikrobiologie (VAAM)

Die Vereinigung für Allgemeine und Angewandte Mikrobiologie (VAAM) (www.vaam.de) ist eine der größten Vereinigungen im Bereich der Lebenswissenschaften. Es ist Ziel der VAAM, mikrobiologisches Wissen für die Gesellschaft verfügbar zu machen, Grundlagen und Angewandte Forschung voranzutreiben und den wissenschaftlichen Nachwuchs nach Kräften zu fördern. Besonders wichtig für die Zukunft der VAAM als mikrobiologische Fachgesellschaft sind die vielen Studierenden, Doktoranden und Nachwuchswissen-schaftlerInnen als aktive Mitglieder. Die VAAM hat aus dem Anlass ihres 25-jährigen Bestehens einen Sonderband herausgegeben, in dem die Entwicklung der VAAM als Fachgesellschaft und die mikrobiologische Forschung in Deutschland dargestellt wird. Dieser Sonderband steht hier frei zur Verfügung und enthält auch alle Informationen über eine Mitgliedschaft in der VAAM. Auf Anfrage wird der Band auch von der Geschäftsstelle verschickt (info(at)vaam.de).

OBAC „Overcoming energetic barriers in acetogenic conversion of carbon dioxide“

PROJECT SUMMARY

Significant focus has been given in recent years to crop-based biomass as the primary feedstock for producing environmentally sustainable fuels and chemicals. However, two key limitations remain. First, the high value and numerous competing uses of farmed biomass (food, materials, fuel and chemicals) constrain its availability for fuels and chemicals, limiting broader economic impacts. Second, environmental benefits are also constrained by uncertainties in global biomass production potential as well as the GHG and other impacts of growing and processing traditional plant-based feedstocks, including indirect land use change. The application of gas fermentation using carbon dioxide as feedstock for fermentation is an environmentally friendly alternative and allows a broad spectrum of carbon-rich wastes that are available globally today to be recycled into valuable chemical commodities, thus reducing society’s dependence on oil and overall GHG emissions.

Microbial capture and conversion of carbon dioxide to biocommodities allows the carbon in the greenhouse gases to be recycled and monetised. A specialized group of bacteria, acetogenic bacteria, are able to achieve this in a fermentation process without requiring light or oxygen. The reducing agent for carbon dioxide used by these bacteria is molecular hydrogen (H2) or carbon monoxide (CO), or a mixture thereof. Indeed, these bacteria grow on a mixture of CO2 + H2 + CO, a gas mixture also known as synthesis gas or syngas. Waste from industry (such as the gaseous residues of established industrial processes), society (municipal solid waste) or agriculture (biomass) can be gasified and used equally well as a resource for the production of fermentable gases and thus as a feedstock for sustainable fuels and chemicals by gas fermentation using acetogenic bacteria. This technology enables the carbon and energy in these waste resources to be recycled to produce valuable commodity platform chemicals and fuels that displace equal volumes of oil-derived products in the value chain. Gas fermentation using acetogenic bacteria has already been demonstrated in two pre-commercial 100,000 gal/yr demonstration facilities deployed at industrial sites to produce fuel ethanol from abundant waste gas resources (by LanzaTech); commercial gas fermentation units are currently in design by LanzaTech and ArcelorMittal, a partner of our consortium.

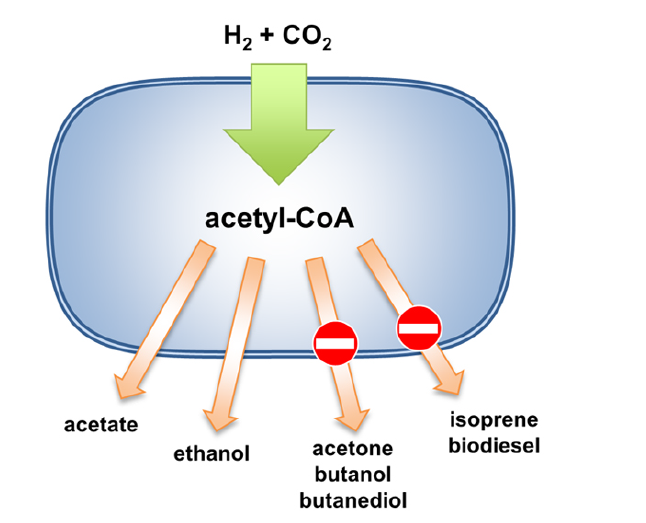

So far, mainly natural bacterial isolates are used. These strains differ in their product portfolio that can be produced from CO2 + H2 with some exclusively producing acetate and others a mixture of acetate and ethanol. None of them is able to produce other platform chemicals (Fig. 1). The nature of the product formed is determined by three main factors: the enzymatic composition of the cell, the energy status of the cell reflected by the ATP content, and the redox balance of the fermentation. These factors also constrain the products that can be formed by metabolic engineering and in particular prevents the production of high energy-demanding gaseous olefins, the core molecules of the petrochemical industry. The overall goal of the project is to overcome energy and redox barriers that limit the products that can be produced from carbon dioxide by acetogenic bacteria and demonstrate the ability of this system to produce energy-demanding industrial bulk chemicals on an industrial scale.

CO2CHEM

Project Summary

Heightened concerns over global warming and fossil fuel supply, security, and prices necessitate the implementation of alternative, sustainable routes to the production of chemicals and fuels. Whilst much attention has focussed on cellulosic processes, particularly through microbial-based processes, this is proving challenging, as are catalytic routes to biofuels from whole biomass. An alternative strategy is to directly capture carbon before incorporation into lignocellulosic biomass. Acetogenic bacteria species, such as Acetobacterium woodii are able to capture carbon (in the form of CO2) through anaerobic gas fermentation and reuse that carbon in products that displace their fossil-derived counterparts. Acetogenic fermentation represents a versatile industrial platform for the sustainable production of commodity chemicals and fuels from diverse gas resources derived from industrial processes, coal, biomass and municipal solid waste (MSW).

We will devise a new sustainable route to the important platform chemical 3-hydroxypropanoic acid (3-HP) using an Acetobacterium woodii chassis. 3-HP is ranked 3rd by the US Department of Energy (DOE) in the list of twelve platform chemicals which can be derived from biomass. 3-HP can serve as a starting point for production of acrylic acid (representing a $ 10 billion market together with the respective esters), acrylamide, malonic acid, poly(hydroxypropionate), 1,3-propanediol, and propiolactone (Figure 1). There is no commercially viable route to 3-HP from fossil feedstocks. From renewable raw materials, BASF, Cargill, and Novozymes recently demonstrated the production of 3-HP. However, identified bioroutes to 3-HP all rely on glycerol, fatty acids, or sugar as feedstocks, which are vulnerable to price volatility and impact food and land availability. In contrast, the use of waste gases will supply an abundant and cheap non-commodity, non-food carbon source, thus dramatically lowering production costs, while concomitantly contributing to climate protection by consuming green house gas emissions.