(Multiple) Dividing Wall Columns 3D-printing in Process Engineering Rotating Separation Devices Absorption and CO2 Capture Industrial Projects

In our research, we always use a combination of theory (modeling & simulation) and experimentation to generate a deeper understanding of equipment or processes. This understanding is the key to optimizing processes or unit operations—for example, in terms of their energy efficiency. We focus on classic fluid process engineering processes, such as distillation or extraction, to name just two. Highly intensified variants of these processes are in the focus of our reserach, such as multiple dividing wall columns or rotating extraction centrifuges. Resource and energy efficiency are the target variables of our optimization efforts. Even though we, as a university institution, often investigate fundamental phenomena, it is deeply ingrained in our self-image to always keep the application in mind. We are, after all, engineers.

![[Translate to English:] Thermal Process Engineering Ulm](/fileadmin/website_uni_ulm/nawi.inst.075/Bilder/7_Logos/TPT-UU_ENG.png)

(Multiple) Dividing Wall Columns

One major pillar of our research. Distillation is the most widely used separation technology in the chemical industry and covers approximately 3% of the total energy consumption. Reducing this amount and thus also the environmental impact of distillation is the core of our research. For this purpose, we investigate a special kind of distillation column called Dividing Wall Column. These allow the separation of ternary mixtures into the pure components in only one column shell by the application of a partitioning wall inside the columns. This results in considerable reductions in capital and operational costs and energy consumption/operational costs, accordingly these columns are nowadays widely applied in chemical industry and can be considered as a mature technology. By adding additional partitioning walls this concept can be extended to quaternary separations. Further reduction of costs and environmental impact becomes likely. However, the complexity of these units is highly increased and none of these Multiple Dividing Wall Columns have ever been realized. After 4 years of development we were able to build the first multiple dividing wall column on mini-plant scale an started operation in November 2021.

In this context, we address a wide range of research questions. In collaboration with Fraunhofer ITWM, we develop methods for multi-criteria optimization, computer-aided decision support, and simulation under parametric uncertainties. On the operational side, we investigate the dynamic behavior of the apparatus, for example during start-up, and the development of control strategies.

Since the application aspect is very important to us, we try to address all relevant issues necessary for the design, operation, and understanding of multiple partition columns in such a way that they can be transferred to industrial applications.

Funded by: Deutsche Bundesstiftung Umwelt (DBU), Az.: 34815/01; Deutsche Forschungsgemeinschaft (DFG), 447448188, 504053721, 504053756 and 440334941

Involved Members: M.Sc. Yannick Waibel, M.Sc. Lorraine Arzner

Additive Manufacturing (3D-printing) in Process Engineering

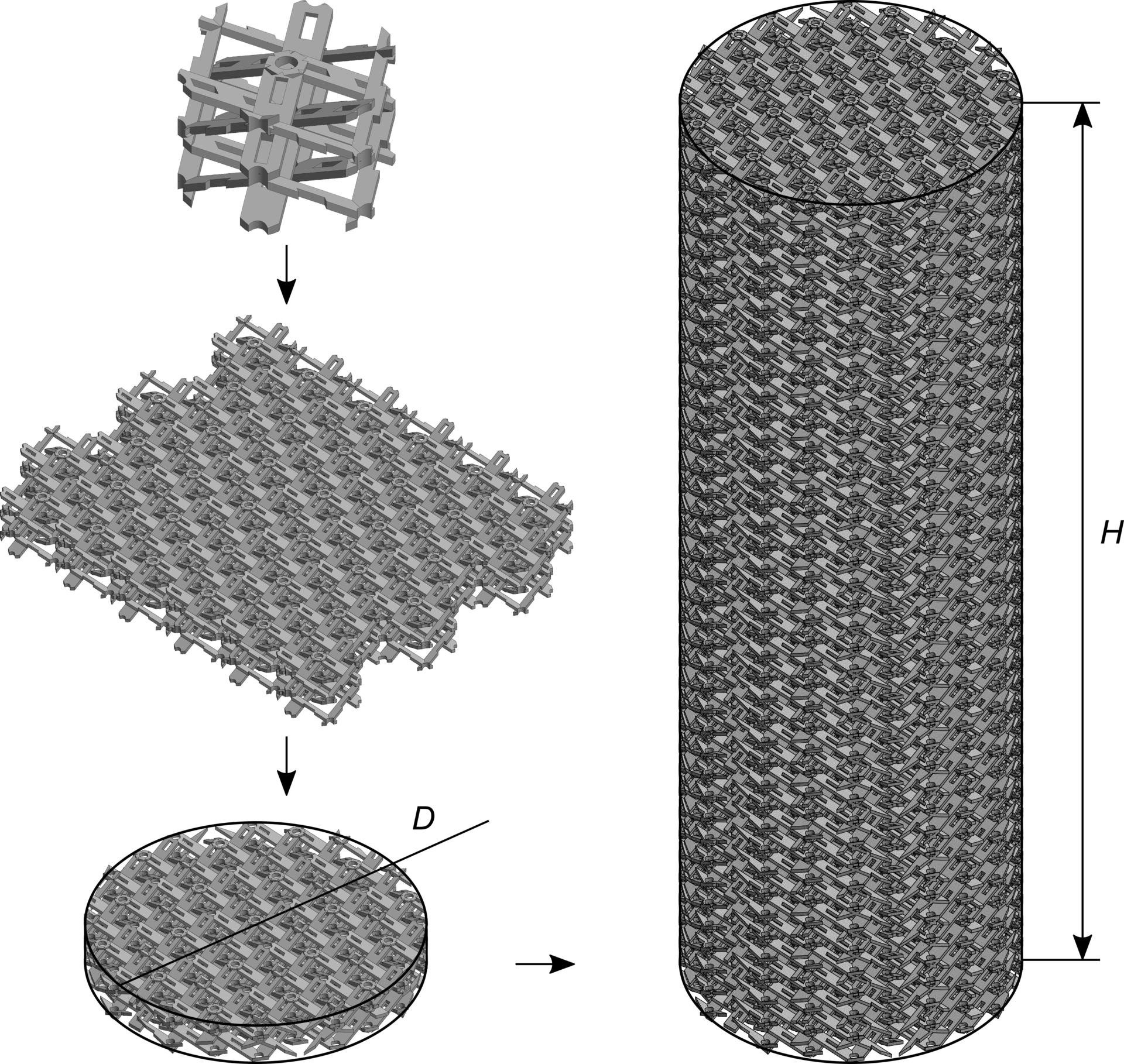

Another pillar of our research. Additive Manufacturing (3D-Printing) allows the generation of components that cannot be made by conventional manufacturing processes. This opens the window to entirely new concepts in thermal process engineering. We are aiming to improve the perfomance and scalability of laboratory equipment with special focus on distillation but also absorption and stripping. For example, we were able to develop printed distillation systems for laboratory applications which, despite a massive reduction in diameter from 50 mm to 20 mm, still allow scaling to large-scale columns. The column internals (structured packings) developed for this purpose show very good performance in terms of separation efficiency (HETP), pressure drop, reproducibility and liquid distribution. In particular, we succeeded in developing packing structures that exhibit virtually constant separation performance over a wide range of gas loading.

Our developments include all relevant components of columns (beside the packing): jacket, liquid distributors, sampling trays, side draw trays etc. All components are computer generated and can be adapted quickly. The development and characterization of the components is based on single- and two-phase CFD simulations as well as experiments conducted using laboratory equipment developed in-house.

In current DFG projects, we are developing fully printed dividing wall columns for laboratory applications and researching their behavior. In addition, we are working in cooperation with the Technical University of Berlin to investigate the interaction of liquids on additively manufactured surfaces. Here, advanced CFD models and experiments are used to understand the influence of the anisotropy of printed solid surfaces on the behavior of film flow and ultimately on the separation efficiency of additively manufactured packings. In this context we are also developing specific technology to measure contact angles on printed surfaces under close to distillation conditions.

The group has its own SLS and SLA printers and extensive analysis technology at its disposal.

Funded by: BASF SE (Ludwigshafen), Deutsche Forschungsgemeinschaft (DFG) 510113776, 533252297 and and from own financial resources.

Involved Members: M.Sc. Adel M. Ashour, M.Sc. Dennis Stucke, M.Sc. Chiara Lukas

Absorption and Carbon Capture

We are currently developing a new strategic field of research in our working group with regard to absorption. The first step is to set up the necessary infrastructure, which includes experimental equipment on the one hand and a toolbox for modeling and simulation on the other. Two small laboratory facilities for (reactive) absorption already exist, one of which is operated by our working group at the University of Ulm and the other by our cooperation partner TH Bingen. Furthermore, a fully scalable absorber (DN125 / H = 8m) is to be set up in our technical center in the coming years. The research questions currently cover three sub-aspects and projects:

1) Tar removal from syngas from biomass gasification

2) CO2 direct air capture

3) Expansion of our column components and packing structures developed for distillation applications to absorption applications.

In particular, research activities focused on the direct removal of CO2 from the atmosphere are of central importance to us. Hence, we are proud to be part of the CDRterra consortium with our own joint research project in collaboration with the University of Ulm (Prof. Dr.-Ing. Robert Güttel and Prof. Dr.-Ing. Thomas Grützner) and the Technical University of Munich (Prof. Dr.-Ing. Jakob Burger and Prof. Dr. Nicolas Plumeré). The CDRterra project is a German federal research initiative funded by the Federal Ministry of Research, Technology and Space (BMFTR) and focuses on land-based approaches for removing CO₂ from the atmosphere (Carbon Dioxide Removal, CDR). The project is being carried out by several university and research consortia across Germany.

In our subproject, we investigate the direct capture of CO₂ from ambient air using industrial cooling towers repurposed as absorbers, as well as the electrochemical regeneration of the solvent employed in the process. We gratefully acknowledge the financial support and look forward to contributing to this exciting and impactful research program.

Funded by: Federal Ministry of Research Technology and Space (01LS2517A) and own financial resources

Involved Members: M.Sc. Simon Brinkmann, M.Sc. Jonathan Bock

Extraction and Rotating Extraction Centrifuges

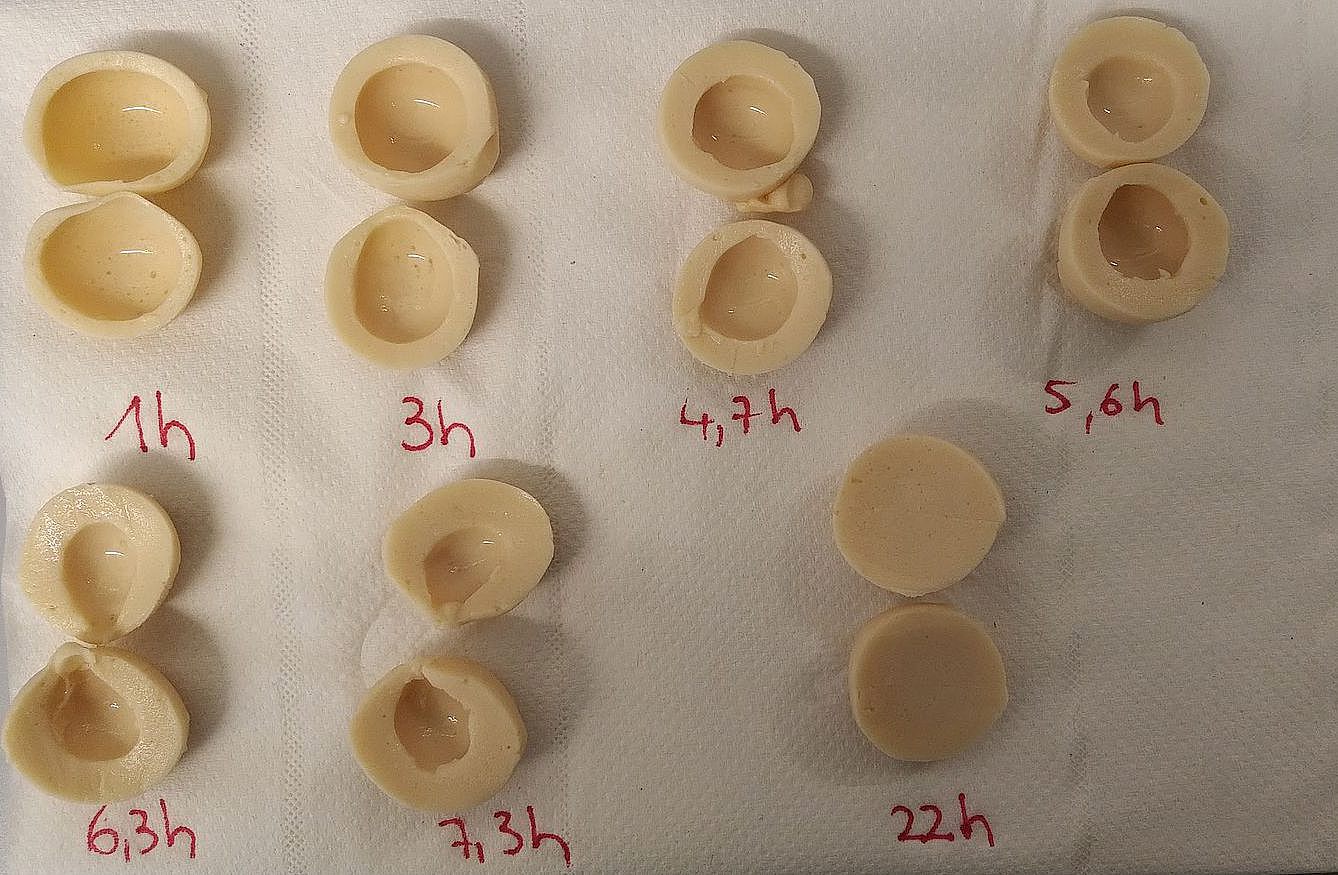

In support of process intensification and modularization, this project focuses on the characterization of a promising centrifugal device for liquid-liquid (L-L) extraction: the annular centrifugal contactor (ACC). ACCs integrate phase mixing and subsequent centrifugal L-L separation in a single unit. Compared to traditional extraction equipment, they offer unique advantages, including compact sizes, rapid establishment of steady-state (within seconds to a few minutes), intense L-L mixing with high mass transfer efficiency and sharp phase separation under high-G fields. Such superior features, however, come at the cost of increased complexity of ACCs in terms of fluid dynamics and process modelling. As these issues are not sufficiently addressed in the previous literature, our research tackles them in two directions: the first establishes a fundamental understanding of ACCs’ complex hydrodynamics, while the second introduces novel techniques to enable both practical and optimized operation of ACCs

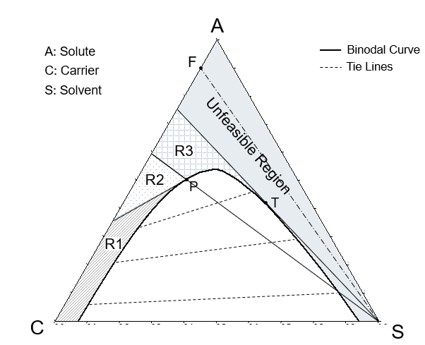

We are also working on fundamental issues relating to extraction and the determination of liquid-liquid equilibria. For example, we are working on the expansion of graphical methods such as the determination of minimum and maximum solvent to feed ratios.

Funded by: DAAD, German Scholar Organization (CSO/CZS 21) and own financial resources.

Involved Members: Dr.-Ing. Zaid Hamamah

Industrial Side Projects

Knowledge and technology transfer to support the domestic economy is an important concern for us. We are trying to close the gap between research and industrial application and are thus open for cooperation projects with industrial partners having questions in the field of fluid separation processes. In addition to our core research interests, we have therefore already dealt with issues in the areas of absorption, reactive extraction, food process engineering and more.

Here are two examples of current projects: Together with a start-up from the biotech industry, we are investigating the separation of low-concentration products from aqueous fermentation broths. Another project involves working with the local sewage treatment plant to recover ammonia from the wastewater produced during sludge digestion.

So do not hesitate to contact us, most likely we can find a solution for your problem.