Electronics

Building O26, Level 1

Management:

Reinhard Liske

phone: +49 731 50-21700

Deputy:

Manfred Kley

phone: +49 731 50-21714

ServicePoint / Warehouse:

Dominik Gaeta

phone: +49 731 50-21713

The following activities and services can be provided in electronics:

Various soldering irons and methods are available for this purpose: regular soldering tips, soldering tweezers, hot air, etc.

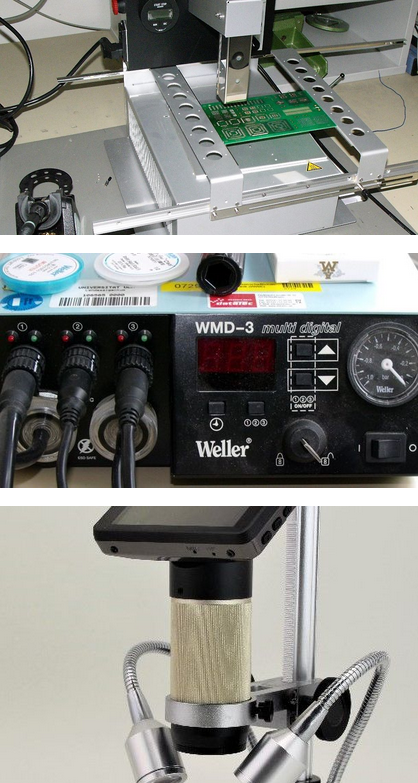

For rework (repair, desoldering, component mounting), there is an IR-rework device. Additionally, we have a Weller desoldering station, a Zevac stereo microscope, several workbench magnifiers, and a camera system.

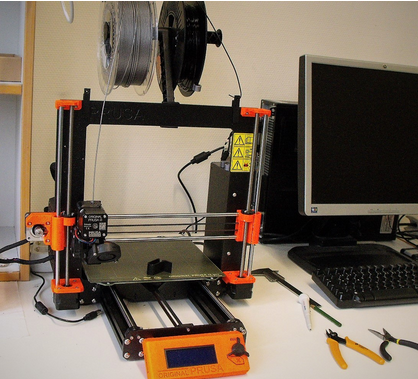

We have a Prusa printer for 3D printing.

For processing housings, we have hand and drill presses, among other things.

For drilling printed circuit boards, there is a special PCB drilling machine.

Conventional chargers are available for charging, discharging, and refreshing regular batteries. An electronic load is available for more precise monitoring of charging and discharging processes.

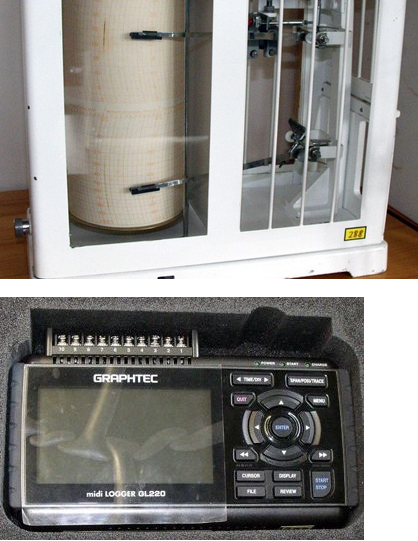

We have various data loggers (10-channel, CO2, temperature/humidity) for the acquisition of changing values over an extended period of time.

For VDE0701/0702 compliant initial and repeated equipment testing, there is an appropriate testing device.

One of our employees is specifically trained for this task.

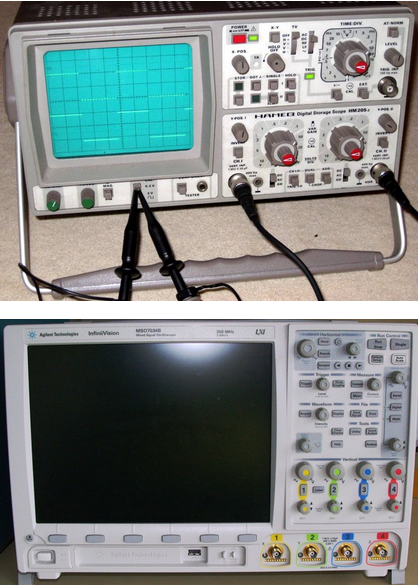

The standard tool for electronics engineers is the oscilloscope. Depending on the model, voltages with frequencies from DC to 2.5 GHz (normally 100 MHz) can be measured.

To generate (test) signals, we have various single and dual-channel signal generators. These typically cover the range from DC to 20 MHz. In addition, there are several different amplifiers and filters to manipulate signals.

For coil winding, we have a semi-automatic coil winding machine. Depending on the coil body, almost any coil up to about 20 cm in length can be manufactured. In stock, we have copper lacquer wire (CuL) in various thicknesses.

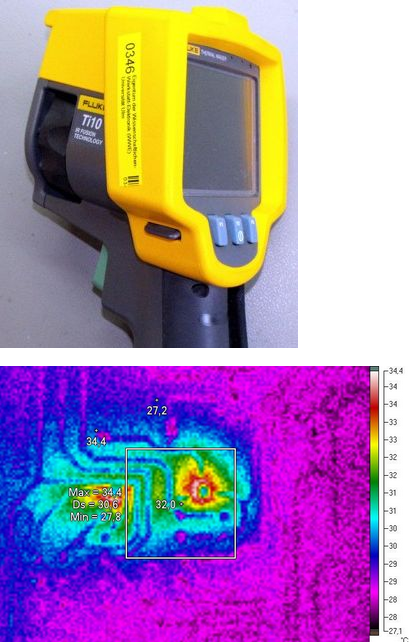

Temperature measurement is of great importance for many devices and setups. For this purpose, we have universal temperature sensors as well as a thermal imaging camera in addition to glass tube thermometers.

To test components/devices at different temperatures, we have a thermal chamber (-100°C to +200°C, theoretically).

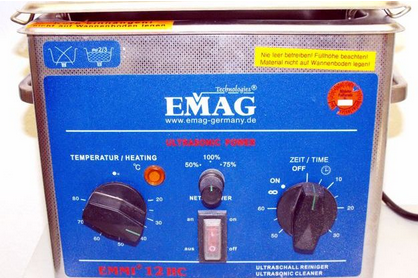

In addition to water and soap, we have a small ultrasonic bath for cleaning tools and components.

Electronics

Building O26, Level 1

Management:

Reinhard Liske

phone: +49 731 50-21700

Deputy:

Manfred Kley

phone: +49 731 50-21714

ServicePoint / Warehouse:

Dominik Gaeta

phone: +49 731 50-21713