CO2 Laser Machining

Overview

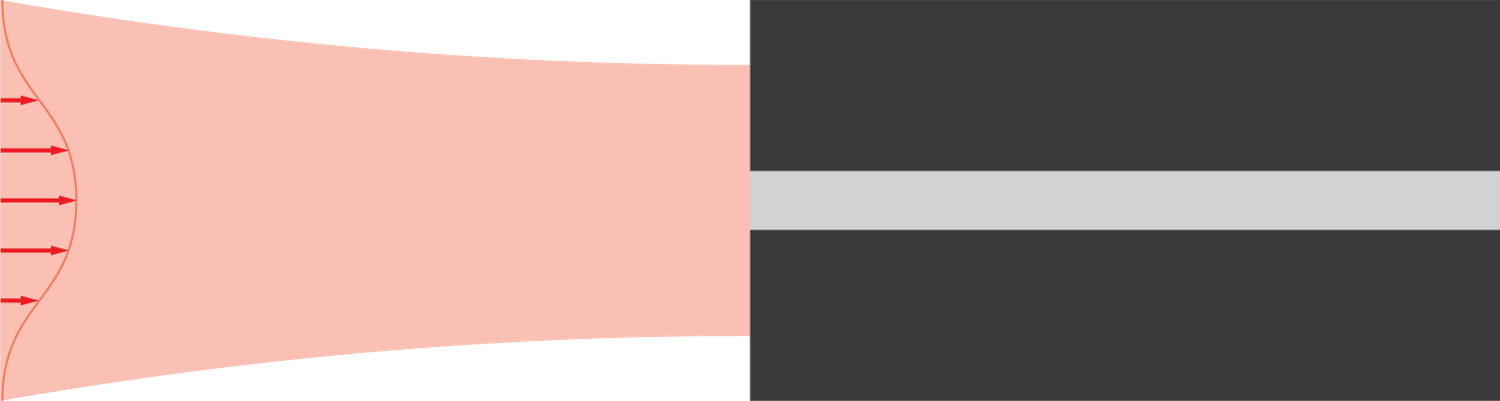

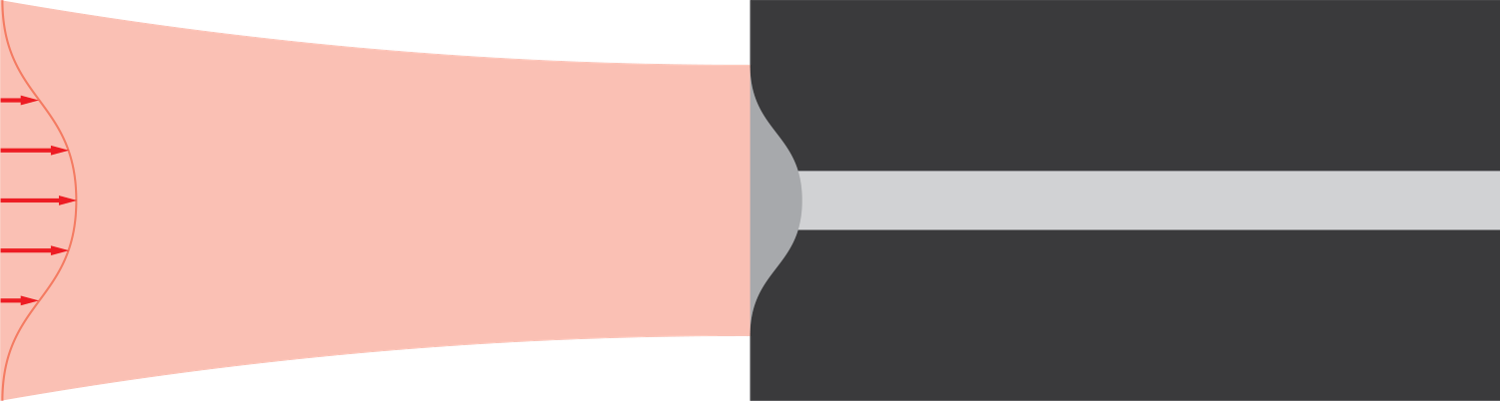

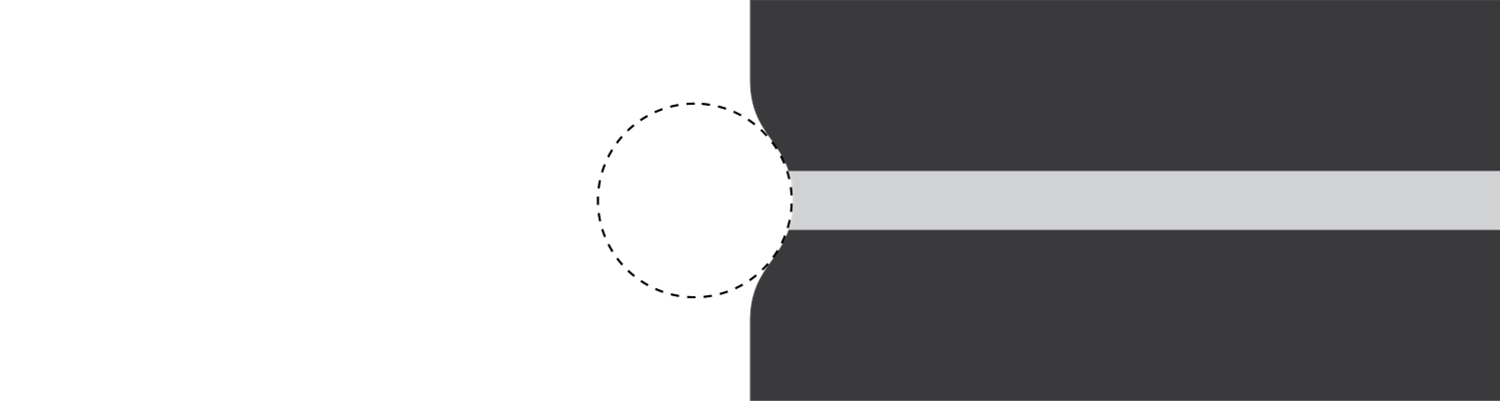

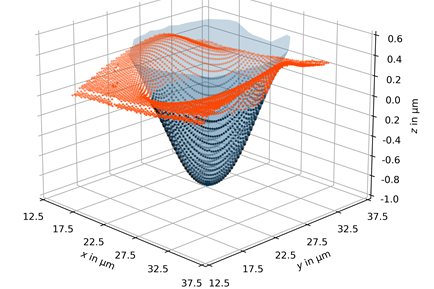

The main task of the experiment is to fabricate micrometer scaled concave structures in variuos materials for their later use in optical cavity experiments. To fulfill the highest demands in terms of surface quality, symmetry and placement accuracy, a Laser based ablation technique is used.

Fabrication Process:

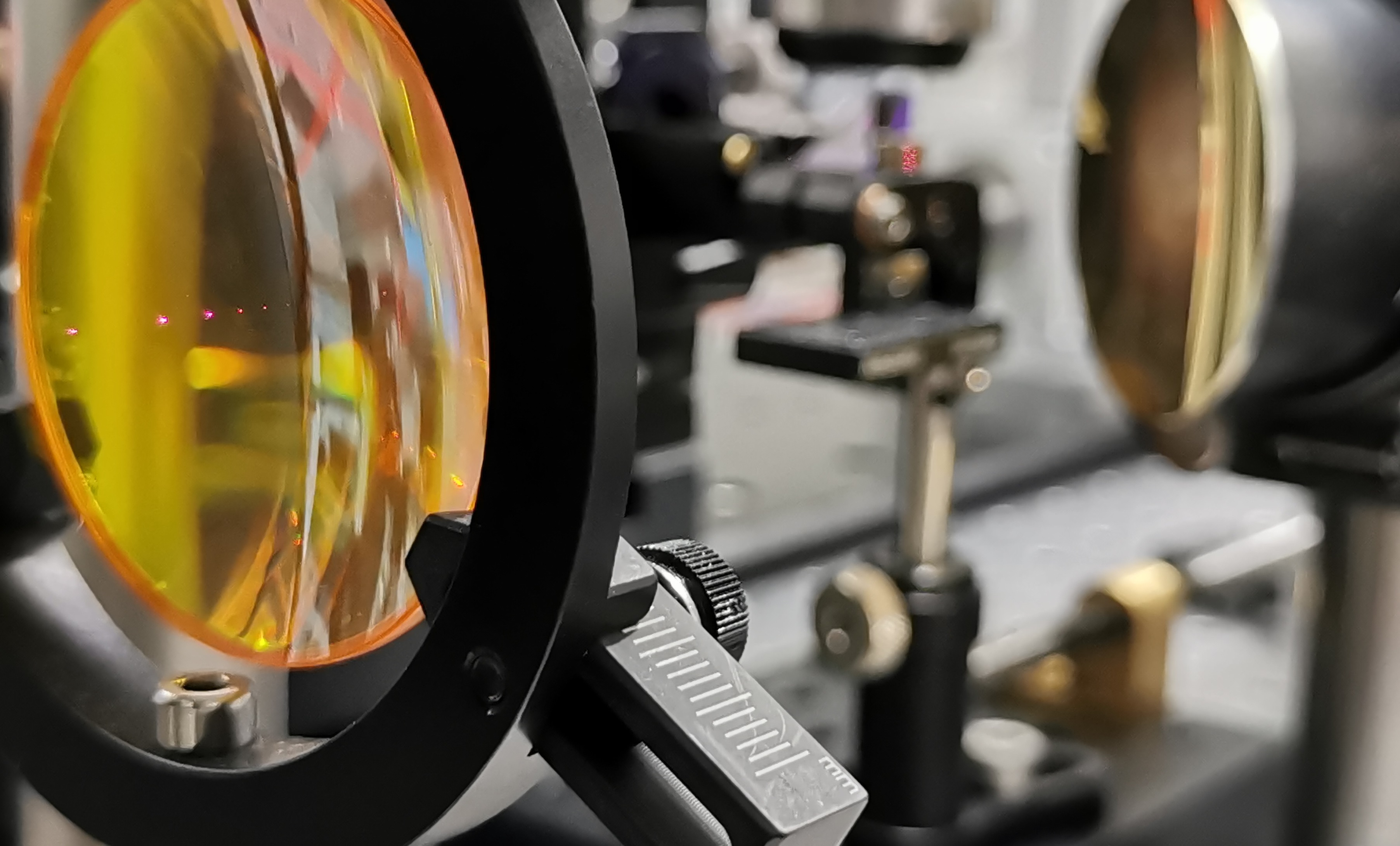

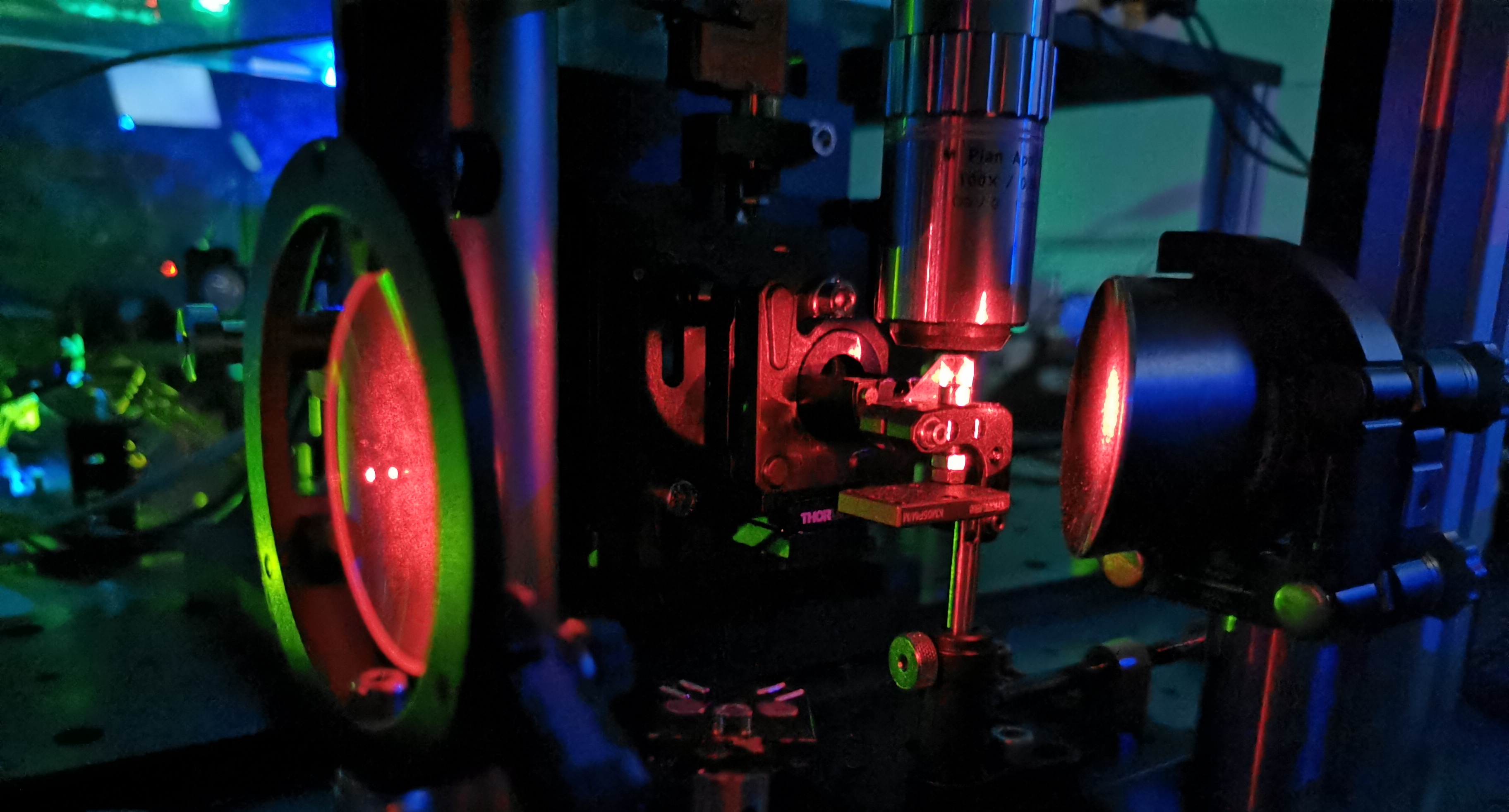

For the ablation a high power CO2 (up to 90W in CW) is focused on the sample. Short pulses evaporate femto liters of volume from the substrate and leave a smooth surface with imperfections on the scale of a few Angstroms.

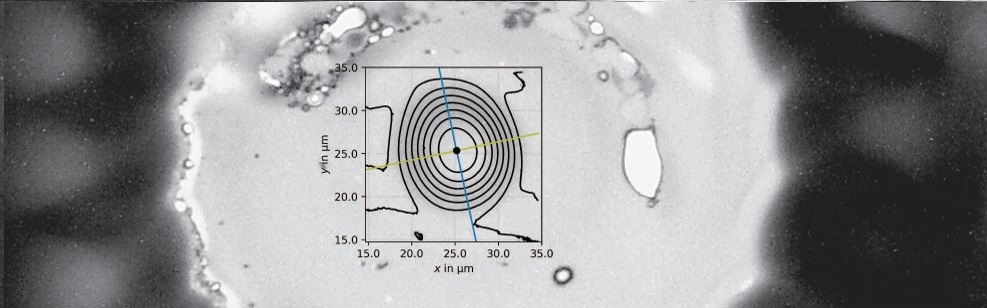

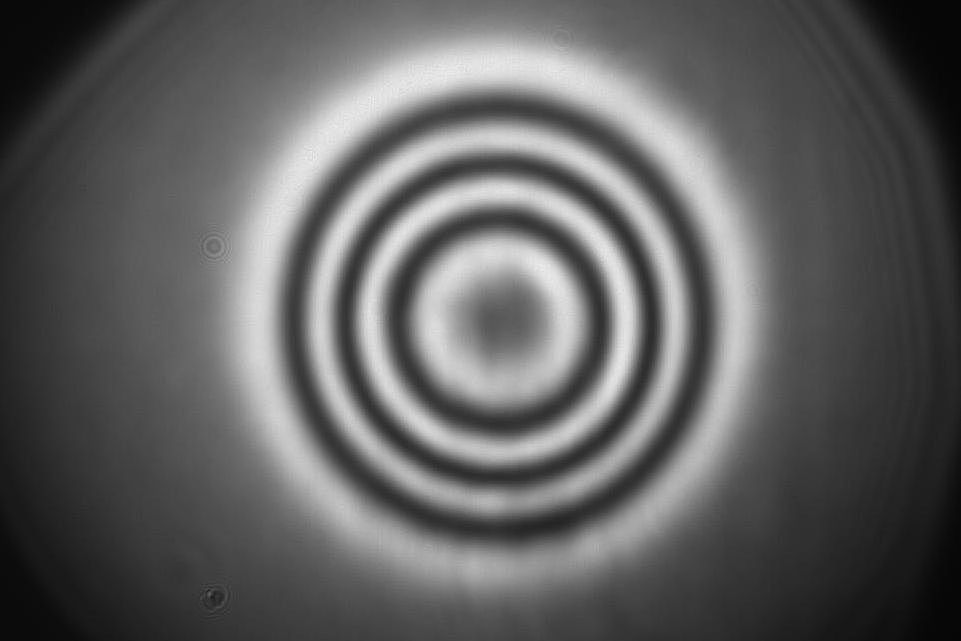

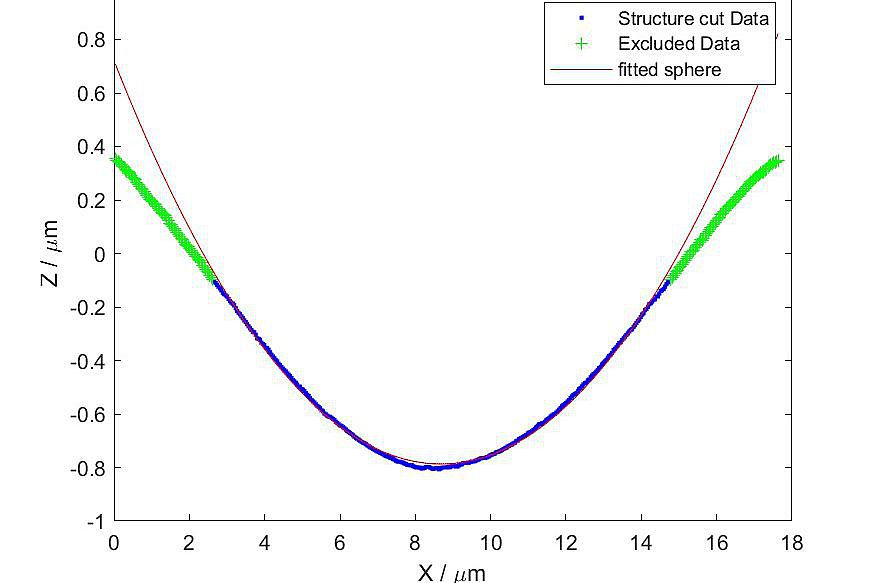

Structure Analysis

Process control is crucial to ensure high symmetry, position accuracy and low surface roughness. To cover all aspects Interferometric Analysis, Atomic Force Microscopy (AFM) and Scanning Electron Microscopy (SEM) are used.

Tasks on the Experiment:

- Optical alignment of an infrared Laser and an imaging interferometer

- Automatisation and Programming of the fabrication process

- Surface and Structure Analysis with Interferometer, SEM and AFM

- Handling and preparation of highly sensitve optcial equipment and samples

- In the near future: Combination with lithographic processes (cleanroom)

Openings

We are currently searching for Bachelor- and Masterstudents who are motivated to join our efforts in producing state of the art custom made optics for wide range applications in cavity experiments. The experiment is used and supervised by PhD students. Also here we are searching for new members on our team. If you are interested and would like to have more information please contact Professor Kubanek.