Electric Mobility Test Rigs

Overview

The Electric Mobility research group at MRM operates a large battery cell test rig for automotive battery cells and an electric power train test rig, which have been substantially extended or built up within the project "XiL-BW-e - Frameworkbasiertes XiL-Labornetzwerk BW für Elektromobilität" (XiL-BW-e - framework-based XiL laboratory network Baden-Württemberg for electric mobility) funded by the Ministery of Science, Research and the Arts of Baden-Württemberg. In addition, the group has a small battery cell test rig available for measuremts of laboratory cells.

Large Battery Cell Test Rig

The large battery cell test rig comprises a temperature chamber, power electronics with integrated measurement instrumentation to test the battery cells, a test rig safety guard as well as a real-time rapid-prototyping control-unit to prove developed algorithms and, at the same time, control the test rig. The temperature chamber allows testing of battery cells under varying operation conditions and provides the required housing with safety equipment for the tests. The actual cell tester with power electronics and measurement instrumentation has 6 individual channels, which can be operated separately or in parallel connection. Additionally, the instrumentation directly allows for electrochemical impedance spectroscopy (EIS). An independent safety guard for the test rig ensures safety during testing.

The test rig has two different control modes: On the one hand, the standard software of the manufacturer is available. Alternatively, the test rig is fully controllable by a free programmable real-time rapid-prototyping control unit. This, on the other hand, allows for integration of algorithms under development for a direct validation during measuring. The real-time control unit additionally allows the networked operation of the test rig with other test facilities within the laboratory network XiL-BW-e.

The battery cell test rig has the following technical characteristics:

- Battery cell tester SL6/300/1.8BT6C by ScienLab with 6 channels

- Voltage range: 0 – 6 V

- Current range per channel: ±300 A

- Parallel connection of 2 – 6 channels for higher overall currents

- Impedance spectroscopy: up to 5 A within frequency range 100 mHz to 5 kHz

- Temperature chamber VTS³ by Vötsch

- Volume of testing chamber: 600 liters

- Temperature range: -72°C – 80°C

- Temperature change rate: up to ±6 K/min

- Real-time control unit MicroLabBox by dSPACE

- Sample time of real-time control: 1 ms

- 1 free processor for algorithms under test

- Additional IOs for further measurements

- Interface for networked operation with other test benches

If you are interested in our test rig, a detailed specification is available upon request.

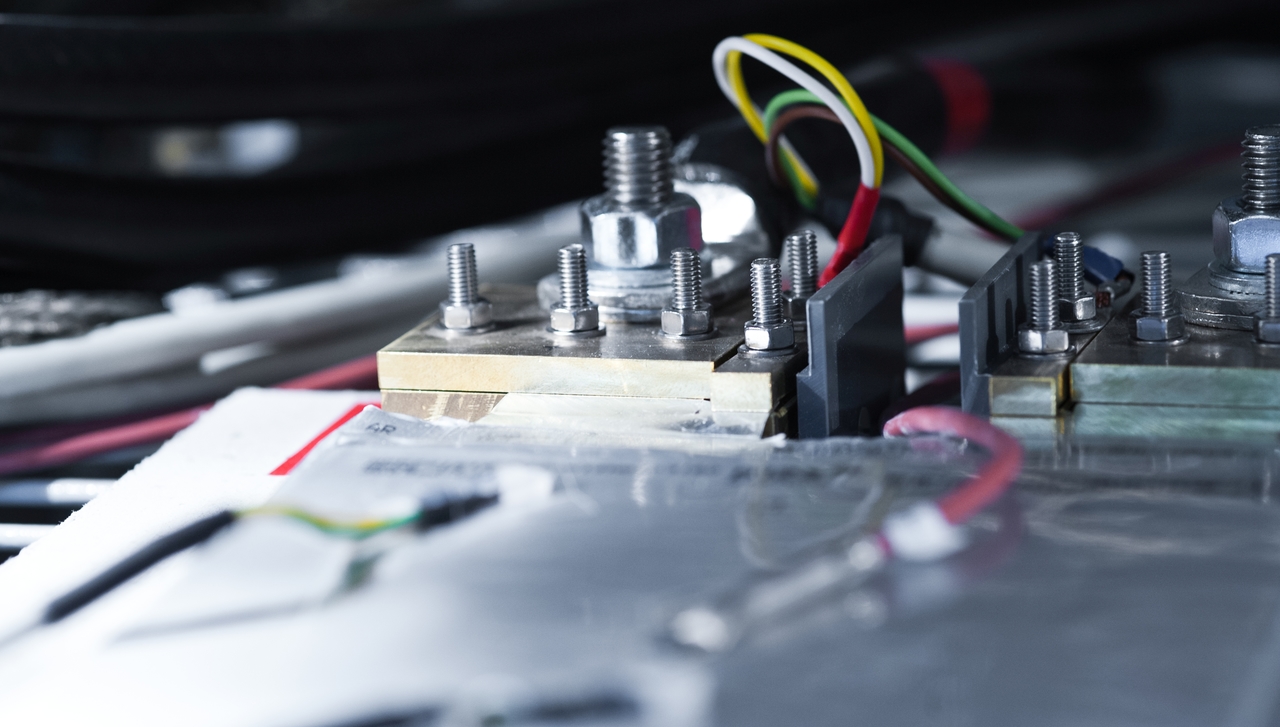

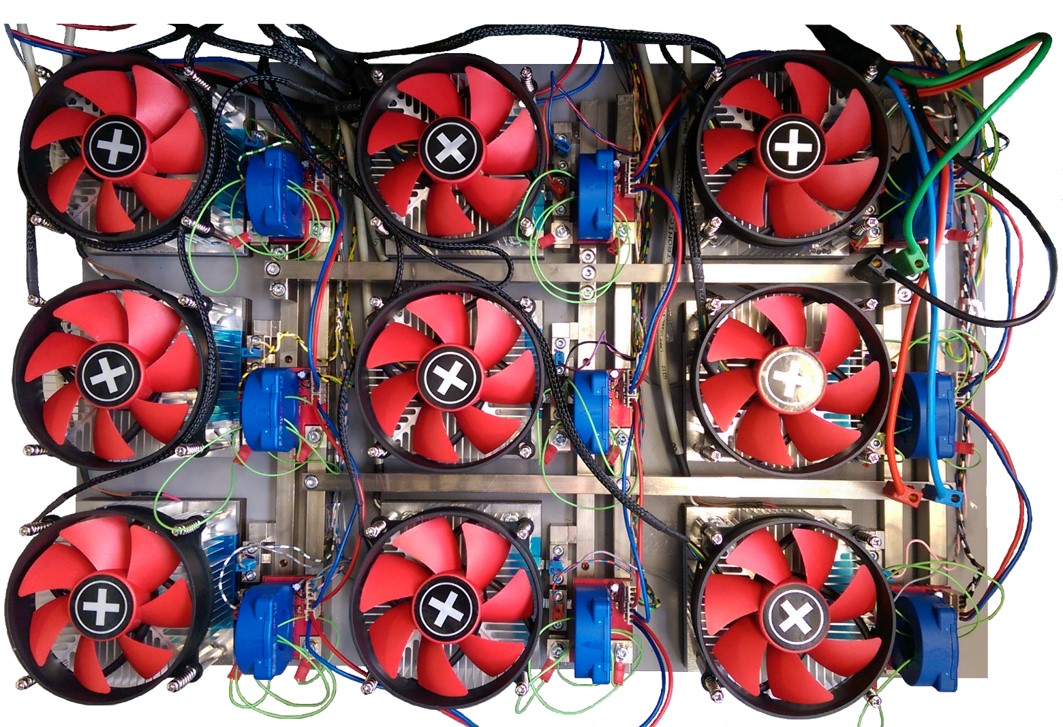

Small Battery Cell Test Rig

The small battery cell test rig serves the evaluation of battery cells with low capacities. such as specially produced laboratory cells or series cells for consumer electronics. The test rig comprises a temperature chamber, a battery cell tester with integrated measurement equipement for imposing cell loads and gaining measurement information from the cells, as well as severel real-time rapid prototyping control units. The real-time control units partly accomplish the test rig control and offer a highly extended measurement capacity in addition to the cell tester. With this large number of analogue and digital inputs and outputs, this test rig especially features meausrements of parallel circuits with small battery cells. The temperature chamber allows for testing with different operating conditions and, at the same time, serves as the safety chamber for the tests. For the evaluation of individual temperature distributions in larger cells or parallel connexions, Peltier elements are available, which can be individually controlled via the real-time units. The cell tester itself features 16 individual channels and allows for single or combined operation. The basic control of the test rig is carried out using the standard software provieded by the cell tester's manufacturer. Additionally, the real-time control units allow for in-the-loop testing of self-developed algorithms with rapid prototyping using MATLAB/Simulink.

The technical characteristics of the small battery cell test rig are:

- Battry cell tester CTS by BaSyTec with 16 channels

- Voltage range: 0 – 6 V

- Current range per channel: ±5 A

- Parallel connection of up to 6 channels for higher overall currents

- Temperature chamber MK115 by Binder

- Volume of testing chamber: 115 liters

- Temperature range: -40°C – 120°C

- Temperature change rate: ±5 K/min

- Real-time control units MicroLabBox and PX10-ExpansionBox by dSPACE

- Sample time of real-time control: down to 1 ms

- 4 prozessors available for algorithms under test

- Additional IOs for further measurements (among others, 96 analogue inputs, 144 digital I/Os, 96 Pt100 temperature sensors via CAN)

More detailed information on the small battery cell test rig is available upon request.

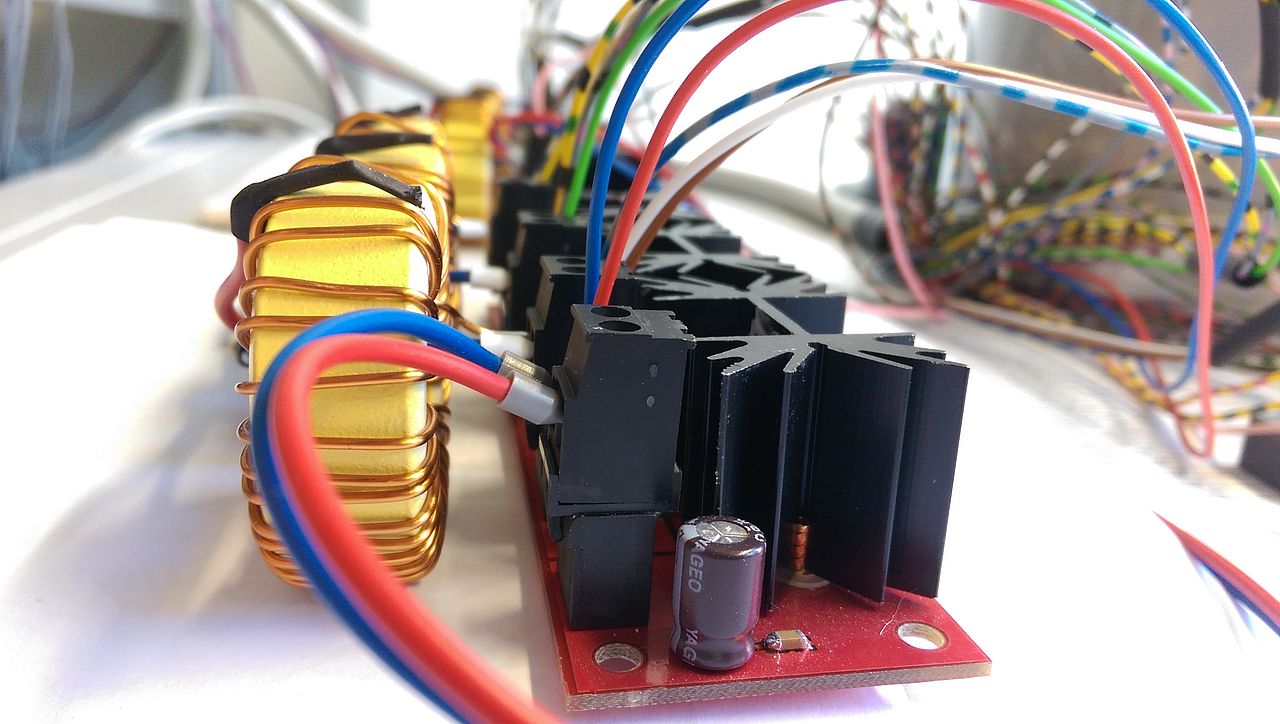

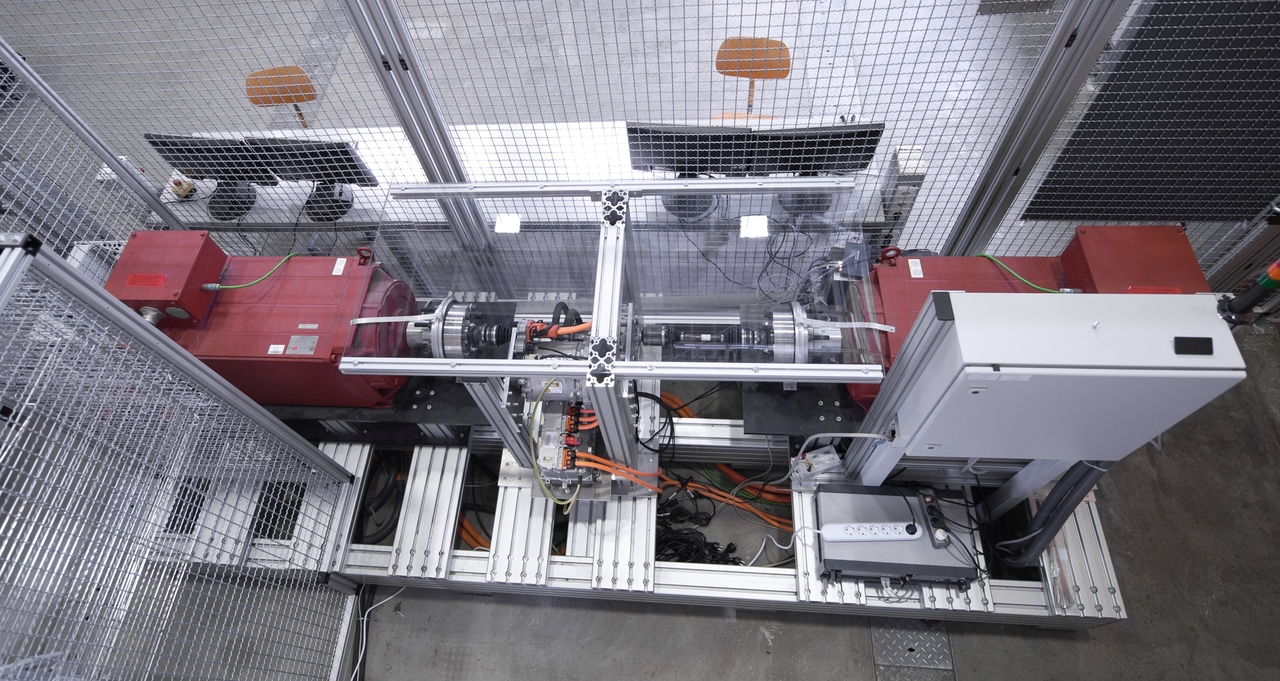

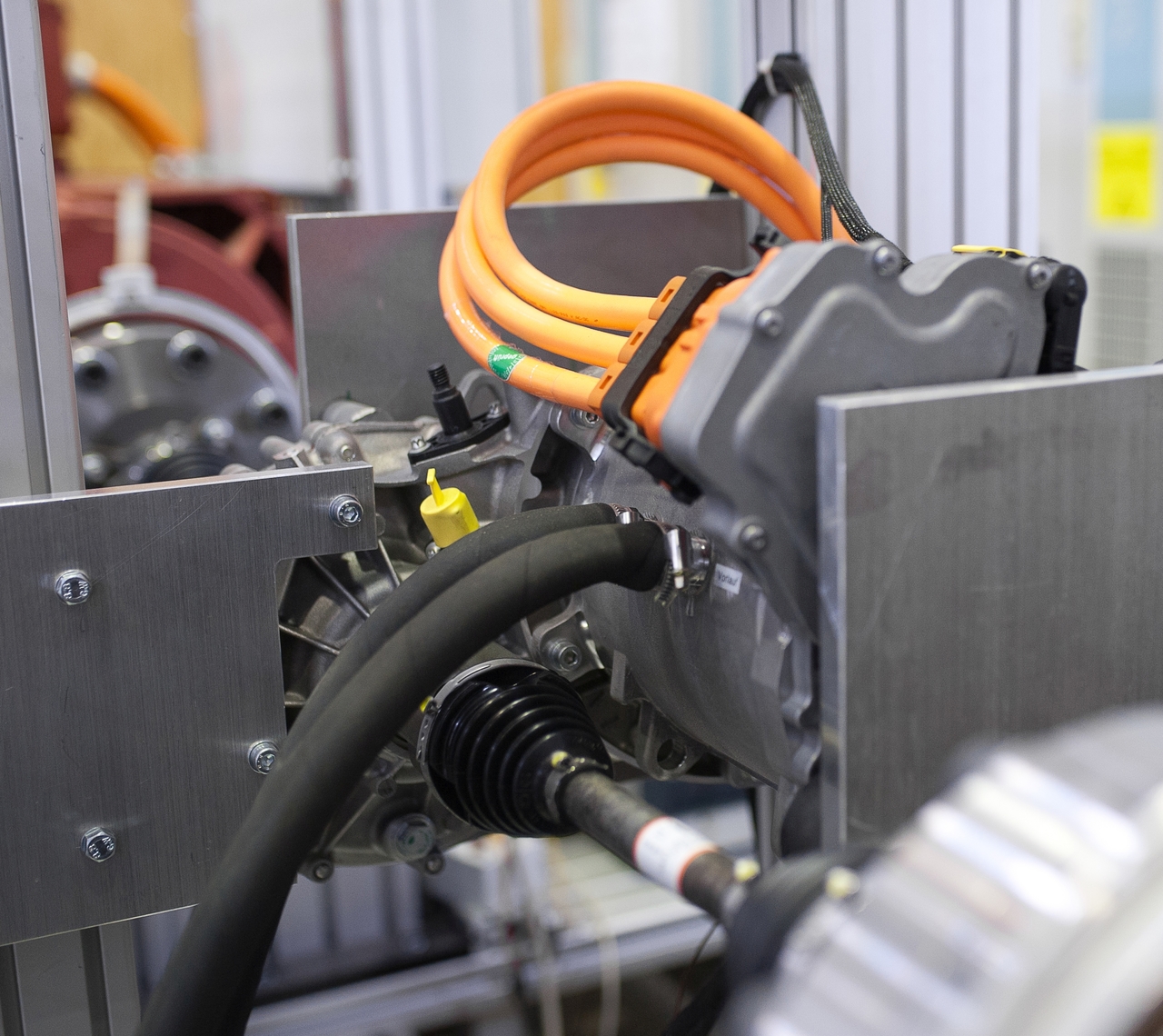

Electric Power Train Test Rig

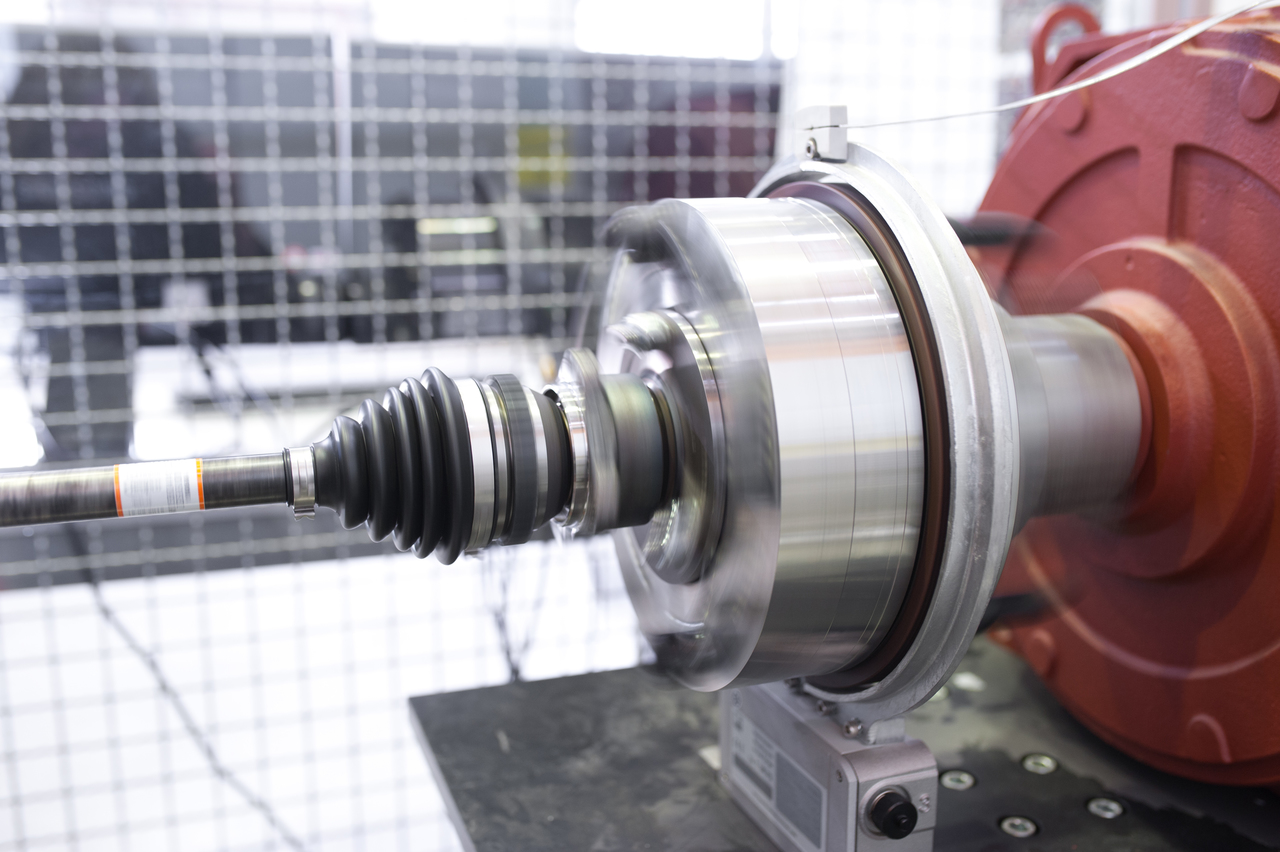

The electric power train test rig comprises two induction machines with corresponding power electronics and measurement instrumentation for the output side of the power train, a cooling unit for the equipment under test, a battery simulator, a test rig control unit and a residual vehicle simulation unit. The induction motors emulate the wheel forces due to driving resistances or mechanical braking at the propelled axis of the vehicle. They are mounted on a machine bed which also holds the electric power train components. Using the cooling unit , these power train components under test (electric motor, mechanical transmission, inverter) can be tempered with usual automotive coolants according to the testing and operating requirements. The battery simulator operates model-based and emulates the behavior of a desired traction battery in real-time, supplying the electric power train under test with energy.

Control of the overall test rig as well as a central data logging are realized by a free programmable real-time control unit (rapid-prototyping system). This control unit is additionally connected to an elaborated real-time simulation of the residual vehicle and it's environment, allowing for realistic testing scenarios with arbitrary driving cycles and vehicle parametrization. The real-time control unit accordingly operates the power train as well as the induction motors and additionally allows for a networked operation with the Battery Cell Test Rig or other test facilities within the laboratory network XiL-BW-e.

Due to the fact that a research focus is laid on vehicle operating strategies and realistic ageing of battery cells (by a networked operation of both test rigs), a standard electric power train similar to that of a Smart Electric Drive is available. This comprises a permanently excited synchronous motor, a dedicated automotive inverter, as well as a transmission including differential. The required residual bus simulation for the electronic components is supplied by the real-time control unit of the test rif via CAN.

The technical characteristics of the electric power train test rig are the following:

- Induction motors by Siemens for wheel emulation:

- Speed range: 0-2000 1/min

- Maximum torque per motor: 1970 Nm

- Power per motor: 75 kW nominal /150 kW peak

- Torque logging by additional torque measurement hubs

- Battery simulator by ARADEX

- Voltage range: up to 600V

- Output power: 160 kW

- Direct integration of real-time battery models within the simulator control or supervisory control by test rig control unit

- Residual vehicle and environment simulation CarMaker by IPG

- Real-time simulation of the vehicle behavior and the driving cycle

- Simulation of different power train topologies (e.g. pure electric or hybrid)

- Visualization of driving behavior

- Real-time control unit MicroLabBox by dSPACE

- Sample time of real-time control: 1 to 10 ms (depending on subsystem)

- Integration of complex battery models and direct control of the power electronics of the battery simulator

- Interface for networked operation with other test rigs

- Electric power train similar to Smart Electric Drive

- Permanently excited synchronous motor SMG180/120 by BOSCH (90 kW power and up to 12.800 1/min speed) with dedicated inverter

- Original transmission including differential of a Smart Electric Drive by Getrag with a fixed overall transmission ration of 1:10

If you are interested in our test rig, a detailed specification is available upon request.

Networked Operation / Laboratory Network

The real-time control units of the large battery test rig and the electric power train test rigs allow for a networked operation. This coupling is signal-based and enables measurements for ageing of battery cells with real electric loads from a power train. These "wheel-to-cell" investigations can help for an early evaluation of new battery cells with real loads including fluctuations and/or stochastic effects occurring in reality, which usually are not (or even cannot) be modelled. The other way round, the battery cell behavior is then scaled up to a full battery and applied to the power train by the battery simulator. Thus, also effects on the power train, e.g. resulting from voltage drop at high loads on a real cell, can be investigated in this assemblage.

In addition to this networked operation of the two locally available test rigs, a networked operation with further test facilities in other research institutions in Baden-Württemberg is available via the laboratory network XiL-BW-e. Exemplary networked testing scenarios are the ageing of battery cells with respect to (dynamic) inductive charging or the behavior of other components in dependence on the battery cell behavior. Further information on the laboratory network can be found on the website www.xil-bw-e.de. Also, more detailed information is available upon request.