PROCEED - PROactive Consistency for EE product Data management

Project Description

New functionalities in the automotive domain are mainly driven by innovations in electrical and electronic engineering. In practice many of the improvements addressed are related to safety (e.g. ABS, ESP) and powertrain (lambda sensor). Regarding future competitiveness in addition, comfort and entertainment become more and more important.

The electrical and electronic components of modern cars consist of various electronic control unit (ECUs), actuators and sensors, which are interconnected via bus systems and which communicate through different protocols like CAN (Controller Area Network), LIN (Local Interconnected Network) and FlexRay. During the lifecycle of a new car, which includes phases like development, production, sales, and after-sales these electrical/electronic (E/E) product data arise in different variants and versions, which have to be documented, revised, and released.

E/E product data are created and maintained by numerous IT systems having different responsibilities, requirements, and focus. In many cases, details of the interconnection of these systems are not documented. Additionally, independently evolving data schemas of the different IT systems lead to diverse data quality (e.g. completeness, accuracy, actuality) as well as unpredictable integration costs through divergent product models of the IT systems.

Contemporary Product Data Management (PDM) Systems focus on the management of E/E product data only on a low (i.e. technical) level, e.g. maintaining technical information about E/E components or geometrical information (i.e. information about the location of the wiring harness). Furthermore, the development process of E/E components follows a bottom-up application and is driven by available ECUs and harness. The increasing number of interconnected ECUs in turn, leads to complex dependencies, which are hard to handle with such a bottom-up design process. In order to reduce development costs, many original equipment manufacturer (OEM) tend to centralize and reduce the number of ECUs. To foster these trends, specialized functions have to be modeled on a higher (logical) level, which result in a top-down development process.

Existing (top-down) modeling tools for E/E architectures are limited to a few domains, but no holistic, business-wide view of E/E product data, which is necessary for consistency and traceability, is available.

Focus of the project PROCEED is the integration of the different, available IT systems, which are involved in the life cycle of E/E product data into one global data schema. As one goal it is possible to support inter-tool-queries and elaborated consistency checks.

Challenges and Requirements:

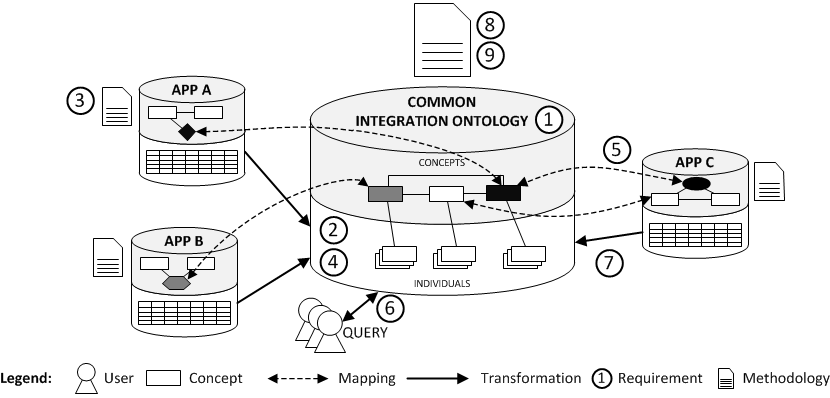

We have elaborated key challenges and requirements for the integration of different, available IT systems (see Fig. 1). The basic idea is to create a common integration ontology, which allows for the integration of artifacts from different application data models.

Challenge 1: Common ontology for data integration

- Creation of a common integration ontology (Req. 1).

- Bidirectional mappings between artifacts (Req. 2).

- Transparency of data model semantics and documentation methodologies (Req. 3).

Challenge 2: Consistency of E/E product data

- Consistency management for E/E product data (Req. 4).

Challenge 3: Data Model Changes

- Maintenance of data model interdependencies (Req. 5).

- Support of impact analysis (Req. 6).

- Transformations between application data models must be derivable from the maintained dependencies (Req. 7).

Challenge 4: Methodology for documenting E/E product data

- Comprehensive documentation methodology, taking current standards into account (Req. 8).

- Modeling methodology for the common integration ontology (Req. 9).

Project Details

Project Team

| Ulm University, Institute of Databases and Information Systems |

| Ulm University, Institute of Databases and Information Systems |

| Daimler AG, Research and Advanced Engineering |

Funding

The project is funded by the Daimler AG.

Duration

The PROCEED project has been running since 2011.